How to classify translucent silicone sheet ?

- Share

- Issue Time

- Dec 7,2019

Summary

silicone sheet classify

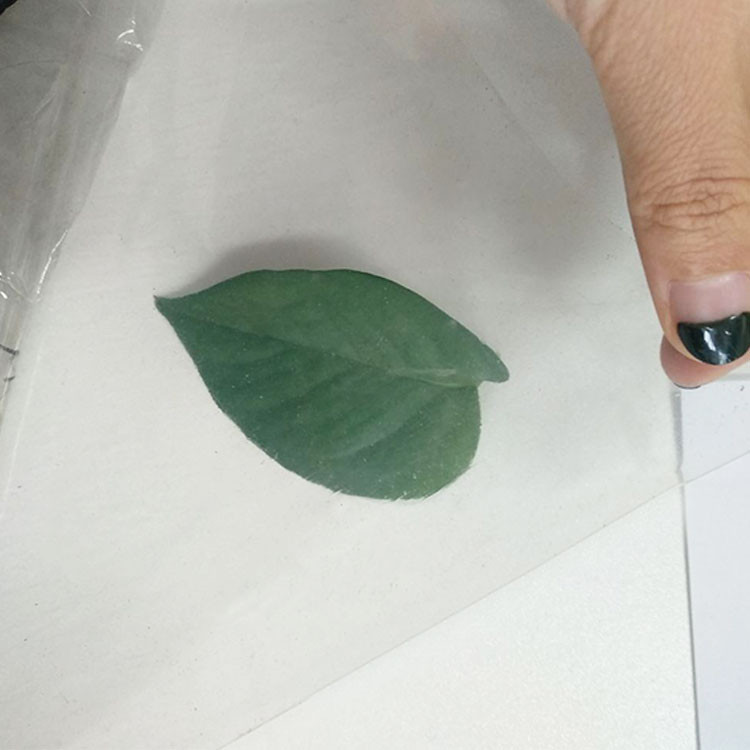

translucent silicone sheet

The silicone sheet is a thin-layer chromatography silicone sheet with high-purity thin-layer chromatography silica gel, mixed with a certain amount of binder, and sprayed on the surface. The characteristics of good and clear spots are widely used in pesticide, medicine, food, herbal and trace impurity and ingredient identification. There are many classifications of silicone sheet, which can be classified according to specifications, coating thicknesses, and also according to molding processes. I will give you a detailed introduction today.

The silicone sheet are classified according to the thickness of the coating, and there are preparation plates and analysis plates. According to the specifications, there are silica gel G, silica gel H, silica gel GF254, silica gel HF254, etc. The different models have different amounts of gypsum, which are mainly reflected in the adhesion of silica gel Different consistency, the higher the gypsum content, the more sticky. Generally, the viscosity of silica gel H is relatively loose and the silica gel G is relatively moderate. According to the molding process, the silicone sheet on the market are mainly divided into two types: molded silicone plates and extruded silicone sheet.

1.Moulded silicone sheet

The molded silicone plate has a fixed length and width, and a fixed size. It is a silicone sheet formed by curing a silicone mold through high temperature vulcanization, and its area is limited. Its advantages are good raw material quality, stable production, consistent size, good control of hardness, color, and raw material grade; its disadvantages are uneven thickness, high cost, 2-3 times that of the extruded silicone board, and low output.

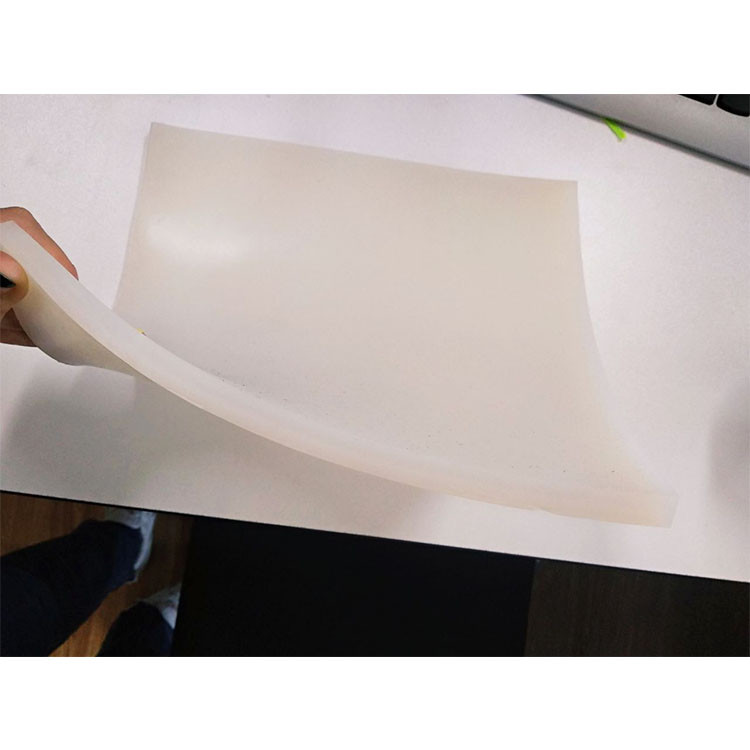

2.Extrusion silicone sheet

The extruded silicone sheet can be freely cut to length, or can be circled together for several meters. The extruded silicone sheet, like the ribbon, is made by an extrusion molding machine. Its advantages are high output, uniform thickness, fast maneuverability and production speed, and low cost. The disadvantage is that the die needs to be matched later to cut out a specific shape.

How to classify silicone sheet? Through the above description, everyone has a certain understanding. The raw material of the silicone sheet is mainly high-quality thin-layer chromatography silica gel. It has a specific surface area, pore volume and pore distribution. It has been widely used at present. To choose the right silicone sheet, please find a professional rubber sheet manufacturer Tianjin Qihang Plastic Technology Co., Ltd. is a professional rubber sheet manufacturer.